Photo credit @CraigHuffmanPhoto Used with permission

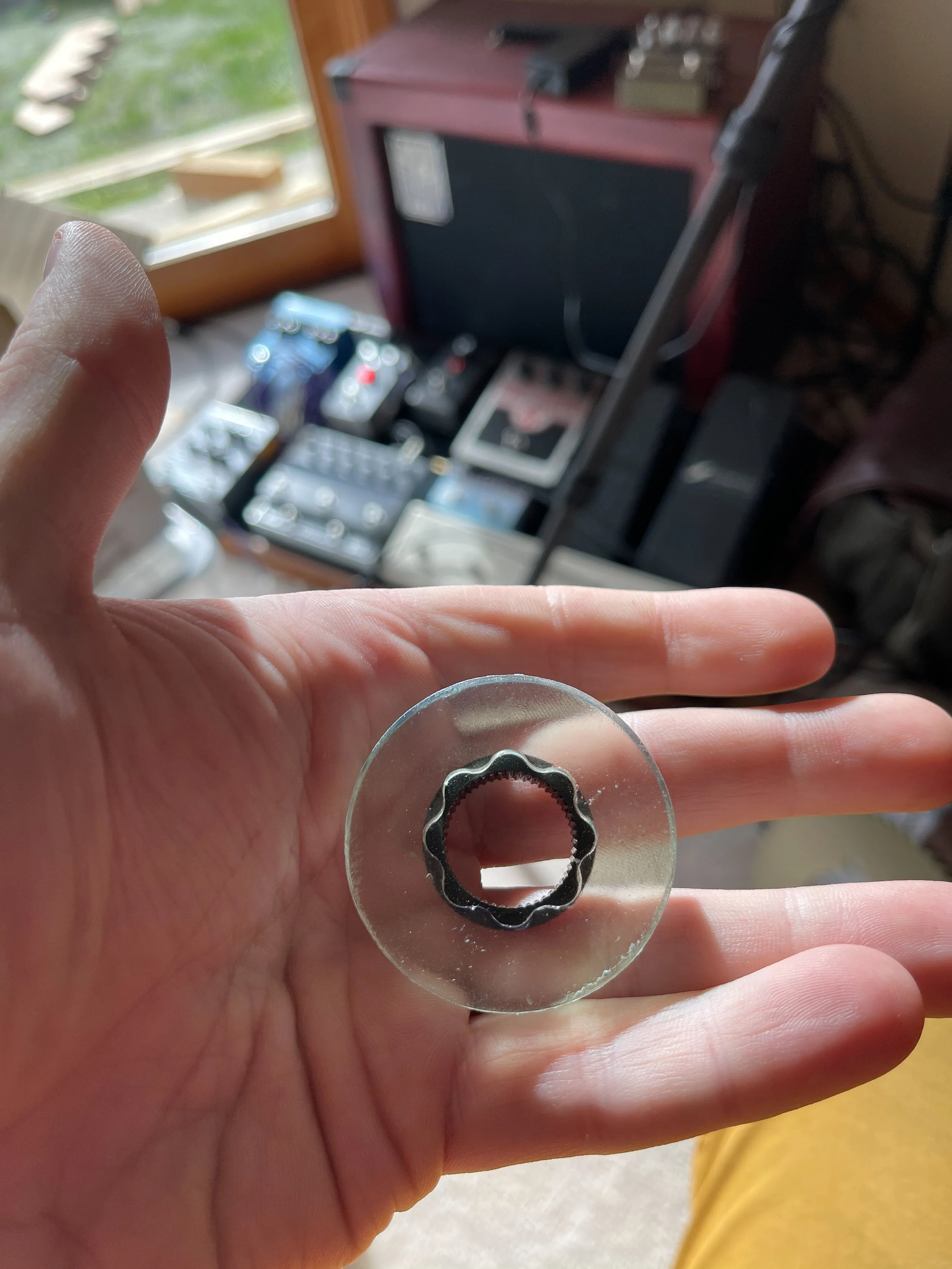

From 3D printed prototypes, to rough machined parts to put in place to deal with the emergency at hand…

Paralympic Tandem Crank Spider

My involvement in this project started when a promising Paralympic team came to my employer’s leadership seeking urgent help in making their track racing tandem hold up to extreme loading conditions. No product made for bicycles was expected to survive the loads these tandems encounter. The main failure mode they experienced was spline failure on their cranksets, causing the loss of drive and possible catastrophic crashes from instability when load would spontaneously disappear to a rider mid-sprint.

Knowing I was the right person for the job, leadership asked if I could volunteer my expertise to help this team, to which I agreed, not knowing the full scope of the project. First it was “Well, it’s a spline that wears out”, which grew to “It’s a custom spline adapter, with an internal spline.” We kept talking and it was clear there was some urgency to this request. I asked when they were planning on leaving for this event they needed parts for. “Three days from now” they replied.

Needless to say, I got to work.

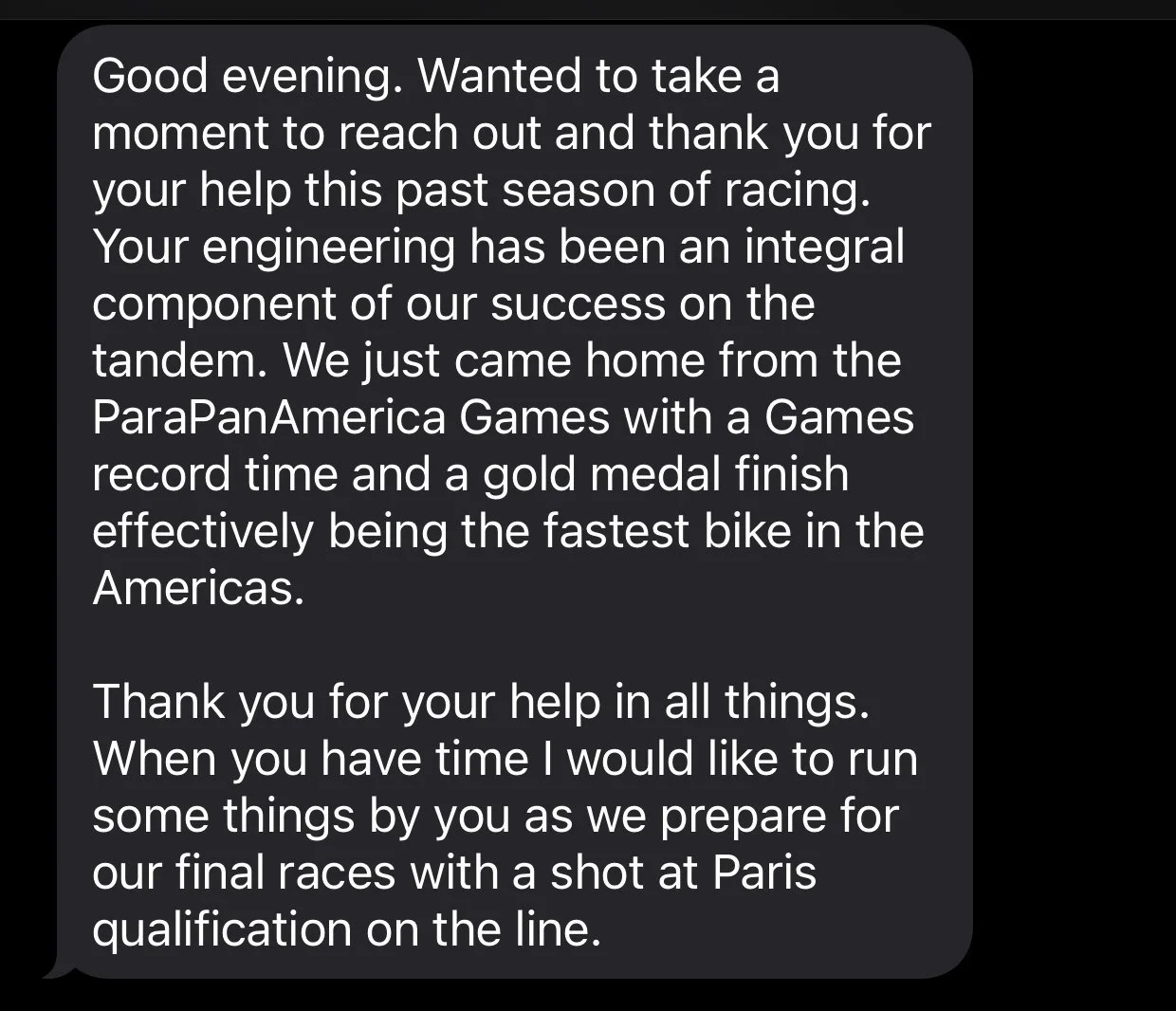

…to low cost, weight-reduced parts to win the ParaPan-America Games…

…to designs for the future made of exotic alloys to truly optimize the design, I’ve been a key part of the ability for the fastest tandem in the world to set new records!